Membrane Roof Drains: Clamp Ring Failure

The wettest part of a roof needs the most protection.

The Situation:

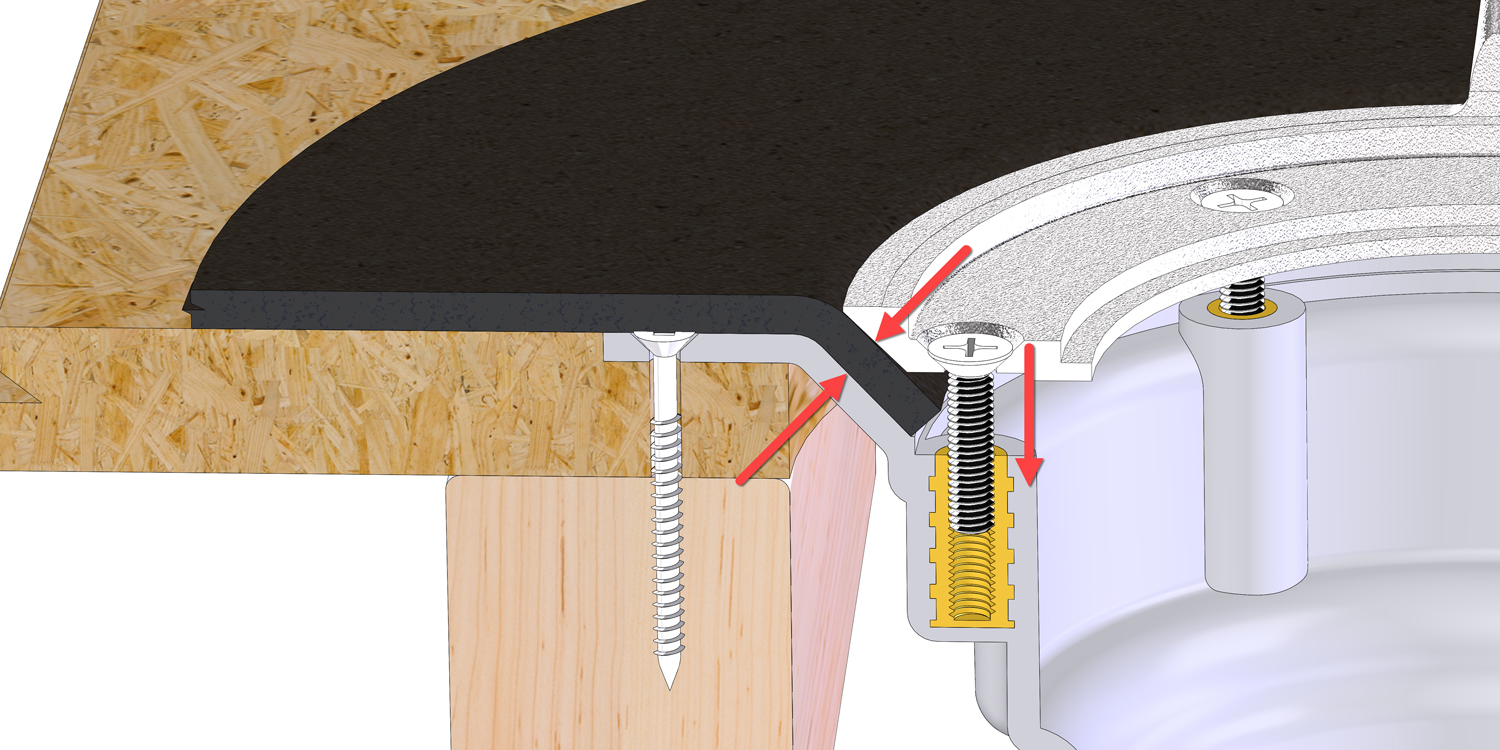

Waterproofing membranes continue to evolve into high-performance roofing systems. Regardless of the membrane system chosen, all rainwater is directed to an outlet, making this area the wettest zone of the entire roof.

To seal a membrane to the outlet, pressure is transferred from fastening screws – through a Clamp Ring- onto the membrane.

Two factors will influence this critical seal’s ability to withstand failure over time:

-

- clamping pressure (torque) generated by the Clamp Ring Screws, and

- rigidity of the Clamp Ring

The existing solutions:

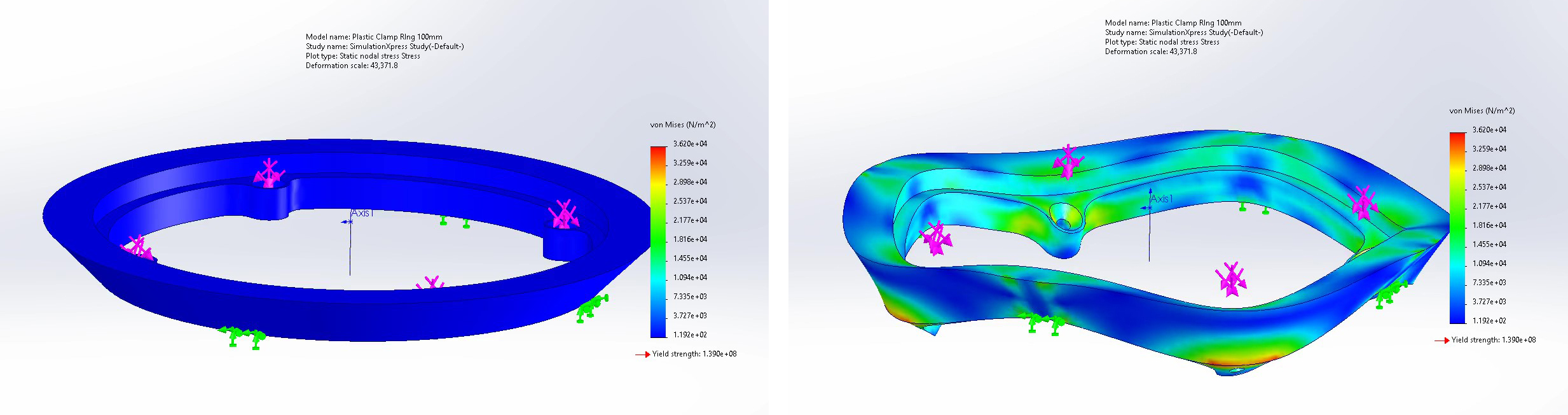

Some commonly available outlets utilise plastic Clamp Rings. Testing of these parts has shown that due to the lack of material rigidity, sealing pressure can only be transferred at points adjacent to the screws.

The perimeter of the Clamp Ring is therefore at risk of leaking.

Our design‐led solution:

All Aquaknight Industries Roof Drain outlets feature Stainless Steel Clamp Rings and machine screws.

This solution generates the required pressure to permanently seal a modern waterproofing membrane drainage system.

The validation:

Tests results

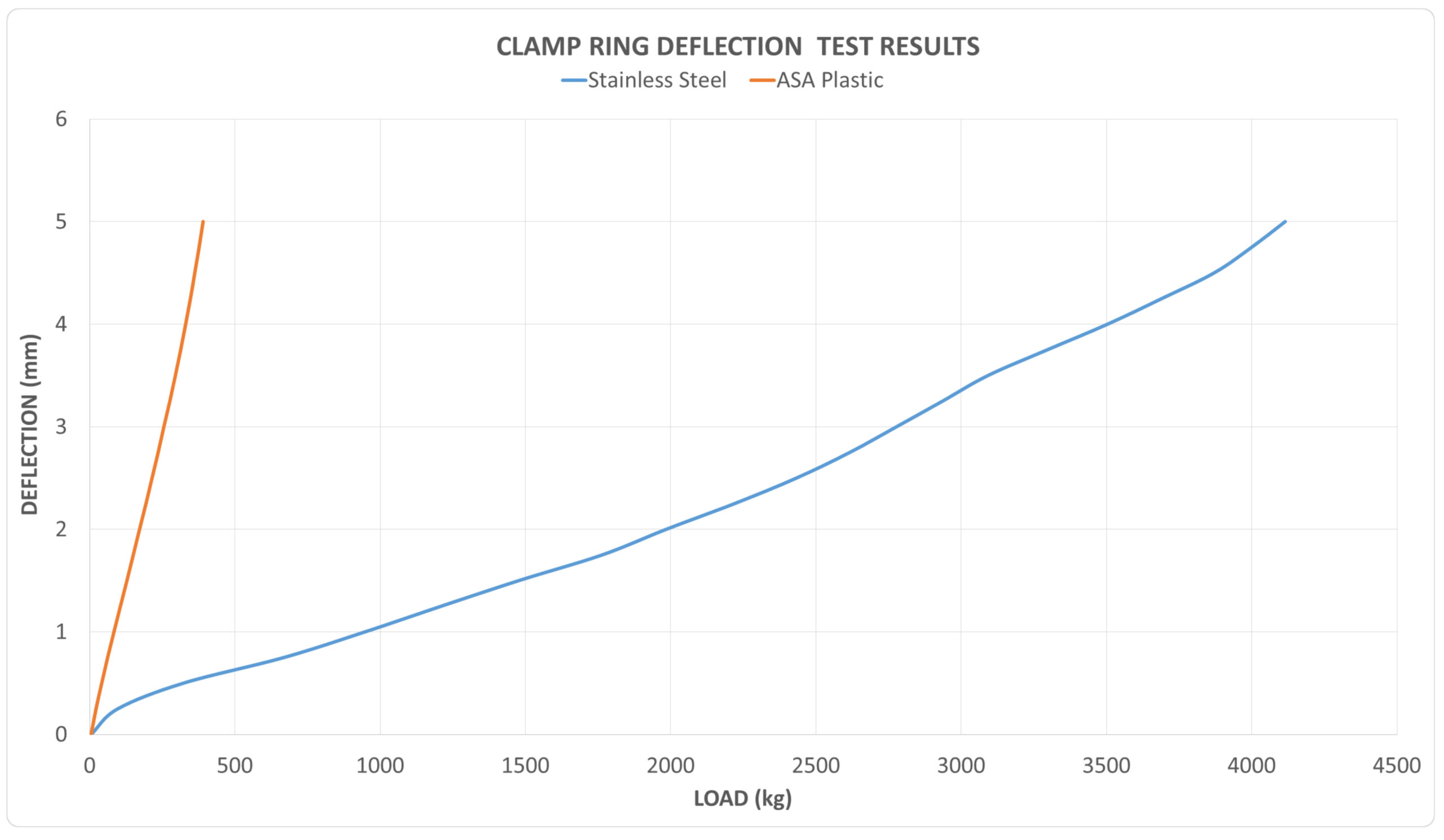

WSP Laboratories conducted standardised deflection tests on both products.

Testing has shown that plastic Clamp Rings deflect at low installation pressure.

Aquaknight Industries Stainless Steel Clamp Rings are ten times more rigid as the plastic alternatives.*

Peer endorsement

At the June 2022 meeting of the Waterproofing Membrane Association Inc, Aquaknight Industries presented these findings.

Concerns of plastic Clamp Ring’s performance and long-term durability were discussed at length.

The association resolved to only endorse the use of Metal Clamping Rings in their Codes of Practice.**

‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐

*WSP Laboratories test report #1-LA639.00